Cloud Adoption Key for Supply Chains

Introduction

In a recent article on SupplyChainDigital, called “How the cloud became a critical to supply chain management” by @Tom Chapman, he explained the reasons why it is critical for supply chain leaders across the world to get rid of old school planning solutions and adopt cloud based planning solutions. And we at Planadigm could not agree more.

In this article, we articulate, highlight and explain a couple of the most important topics from the article which we think are compelling reasons to start to use cloud-based planning platforms:

- Real-time data sharing & collaboration

- Scalability

- Greater agility and responsiveness to market dynamics

- Unified views across (extended) supply chains

- Use of AI & ML capabilities

And we added a few of our own based on our experiences from the field:

- Latest technology used

- Enhanced data analytics

- Key planning functionality out of the box: scenario planning

- Use of external as key prediction metrics

Keep reading for a more detailed explanation.

Advantages moving to cloud-based planning solutions

Real-time data sharing & collaboration

With cloud-based planning solutions it is so much easier to share data across (other cloud based) applications. This is incorporated in the use of the latest technology; the builders created an open platform to easily transfer data between applications. Legacy systems are placed (in most cases) behind your firewall to perform a set of specific tasks, the integration of external was not one of these tasks.

With a cloud-based platform, the collaboration in a organisation has become much easier as well as connecting your most important suppliers and customers to the same platform. Adding new users and granting the right access levels is done in minutes, so scaling up or down is very easy to do. By adding external parties to become part of your planning process, allowing for early warning signals to ripple through the supply chain quickly and the ability to respond early.

Scalability

With cloud-based solutions, you can start small. In the number of use case(s) that you implement as well as the number of users. After a successful implementation of the first use case, you can extend to the next and add new users with just a few clicks. Scaling up or down has never become so easy and most cloud-based providers allow for that flexibility in their contracts.

Greater agility and responsiveness to market dynamics

Most cloud-based solutions allow for small adjustments by the end users due to the ease of use and modelling of the required functionality. Therefor planners can easily adjust the underlying calculations in the business model if required without the reliance of external consulting partners.

Also the creation and adjustment of scenarios with just a few clicks helps planners to model the future based on ‘what-if’-functionality. When a scenario comes to life, this can be used as the new plan in just a few clicks.

Unified views across (extended) supply chains

As mentioned above, you should allow your 20% most important suppliers to be connected to your cloud-based planning solution. Early warning signals if your supplier cannot deliver (for whatever reason) is shown on your dashboards as an alert, so you can respond accordingly and in time. Also the other way around, if you get in a tender causing a peak in your demand, your suppliers can respond quickly and in time to deliver the required materials.

Use of AI & ML capabilities

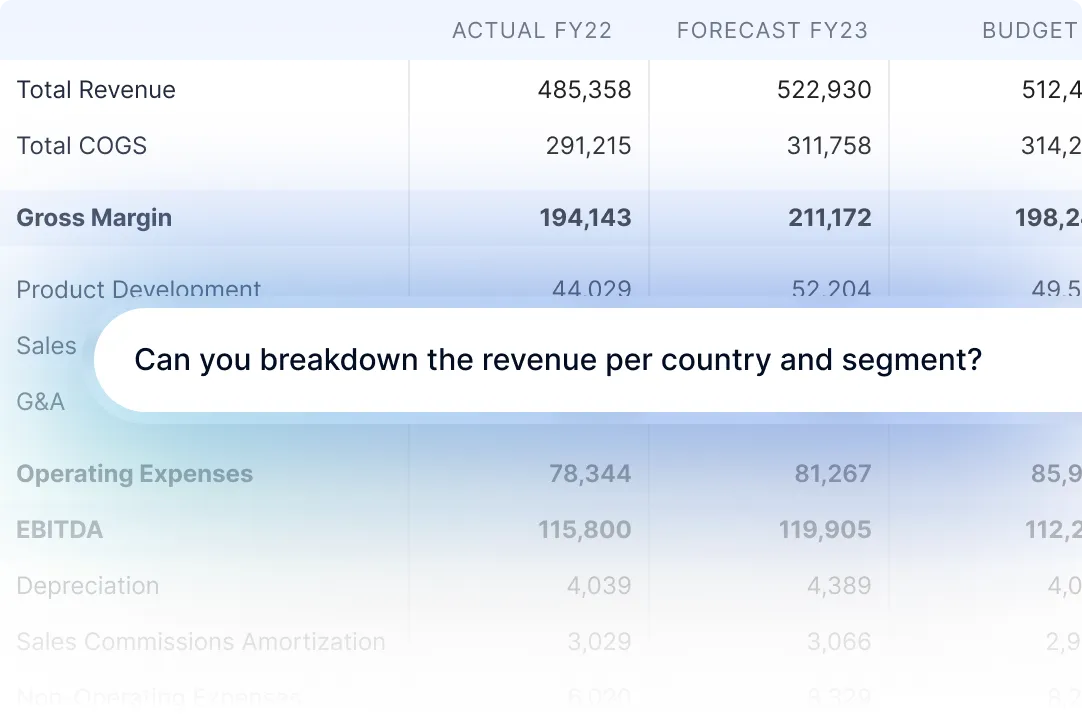

Cloud based solutions based on latest technologies allow for a smooth integration of AI-functionality (generative AI) and Machine Learning (ML) algorithms. Generative AI will help planners in analysing the data in a more intuitive way based on Q&A to deep dive into specific issues and data points. ML can support the increase of forecast accuracy (as we have seen from close by at one of our customers).

Additional advantages

Latest technology used

Recent cloud-based solutions are based on low-code/ no-code technology. Besides the open platform and the ability to connect data from other sources with much ease, this technology has a few more advantages.

It can incorporate recent technology very quickly due to the open platform. The integration of generative AI is a great example of that. While legacy systems are struggling to get it incorporated, cloud-based solutions have it up and running quickly.

Also new functionality (for example: new types of charts, integration of collaboration tools) is much easier and faster to implement compared to legacy systems, extending the functional scope to support the end users.

Enhanced data analytics

Cloud based solutions also allow for greater data analytics. The ability to create graphs and KPI’s in just a few clicks, the ability to drill down from a high-level number to a next level of detail, all allow for great data analytics functionality. With generative AI that functionality is even further extended. And a picture tells more then thousand words, so the ability to show any data in a graphical way enhanced the analytics capability.

Key planning functionality out of the box: scenario planning

What a lot of companies are not doing but should be doing is scenario planning. With a cloud-based solution as Pigment, that has default, out of the box functionality. Create your planning models based on requirements and just before go-live, enable the scenario functionality. And create new scenarios on the fly, just like that. To start to bring forward different futures, for example one where a competitor performs a promotion, resulting in a 10% decline of your sales. Or one where your raw materials increase in price by 18% overnight, what is the bottom-line effect?

Use of external data for key prediction metrics

Another great option that is allowed by cloud-based solutions is the integration of external key prediction metrics. @Lora Cecere is promoting an outside-in approach for supply chains (Outside-in Planning Handbook), to look for external factors that have a predictive foresight to your demand. An example could be the Point of Sales (POS) data from retailers if you are a manufacturer of peanut butter and do not have access to consumer sales data. It could also be the public available data from local governments for new granted housing projects for a manufacturer of construction material.

The cloud-based platforms allow for an smooth and easy integration of this data to incorporate their predictive capabilities once you have access to the data.

Conclusion

The mentioned article by SupplyChainDigital expressed what we believe is the future of planning solutions. In this article we added a few additional reasons based on our own experiences. Are you using cloud-based solutions already? Excellent! If not, you need to contact us ASAP!