Transforming Your Supply Chain with Atomic Habits and a Cutting-Edge Tool

Author: Mike Huiberts

Introduction

In the complex and fast-paced world of modern business, supply chains play a pivotal role in connecting the dots, from suppliers to manufacturers, distributors, and customers. The efficiency of these intricate systems directly influences the bottom line of organizations. In our quest for supply chain excellence, we find inspiration in the best-selling book “Atomic Habits” by James Clear, which underscores the power of small, incremental changes in achieving substantial long-term improvements.

“Atomic Habits” presents a four-step loop – cue, craving, response, and reward – as the blueprint for habit formation. In the context of supply chain management, this framework provides a structured approach to identifying the cues that trigger inefficiencies, creating a strong desire for enhanced efficiency, responding with well-planned changes, and ultimately reaping the rewards of a streamlined and cost-effective supply chain.

Yet, the transformative potential of “Atomic Habits” extends beyond adopting positive habits. It also provides insights on how to eliminate bad habits, inverting the four-step loop: invisibility, unattractiveness, difficulty, and unsatisfactoriness.

In this blog post, we delve into the synergy between supply chain management and the principles of atomic habits. We will uncover how to identify cues, create a craving for positive change, implement strategic responses, and reward progress. Furthermore, we’ll learn how to make undesirable practices in the supply chain invisible, unattractive, difficult to continue, and ultimately unsatisfying to pave the way for transformation.

To supercharge this transformative process, we’ll introduce a cutting-edge tool, Pigment, a cloud-based planning solution designed to seamlessly integrate with your existing supply chain infrastructure. With real-time data, analytics, automation capabilities, and a focus on aligning with the principles of atomic habits, Pigment is poised to revolutionize the way you manage your supply chain.

Continue reading to unravel the potential for remarkable change within your supply chain by harnessing the power of atomic habits and leveraging the innovative capabilities of Pigment. It’s time to unlock the full potential of your supply chain, setting the stage for a more efficient, adaptable, and ultimately, a more successful future in the world of business.Understanding Atomic Habits.

“Atomic Habits” suggests that making small, consistent changes can lead to significant improvements over time. In the context of supply chain management, this means identifying the cues that trigger your supply chain issues, creating a craving for better efficiency, responding with strategic changes, and ultimately reaping the rewards of a more streamlined and cost-effective supply chain. Furthermore, James Clear writes how to get rid of your bad habits which is the opposite of how to adopt a new habit. It is also a 4-step loop but inverted; invisibility, unattractive, difficult, and unsatisfying.

Implementing Atomic Habits in Your Supply Chain

- Identify Your Supply Chain Cues:

The first step in improving your supply chain is identifying the cues or triggers that lead to inefficiencies. This could be late deliveries, stockouts, quality control issues, or communication breakdowns. Analyzing historical data and feedback from your team can help you pinpoint these cues. Whenever you are realizing that there is a hurdle in the process that you need to circumvent that is your cue to act.

- Create a Craving for Improvement:

Once you’ve identified the cues, it’s crucial to create a strong craving for change within your organization. Share the data and examples of how improved supply chain management can lead to cost savings, higher customer satisfaction, and increased profits. Make the entire team understand the benefits of change. The benefits should speak louder than the labor it will cost to implement the process to change. Some employees can seem reluctant to change since they are used to circumvent the problem. Therefore, you need to implore the benefits of the final result.

- Implement Strategic Responses:

Now comes the core of atomic habits – implementing small, actionable changes to address the cues. This could involve optimizing procurement processes, enhancing inventory management, improving communication with suppliers, or automating certain tasks. The key is to make these changes manageable and sustainable.

- Reward the Improvements:

Acknowledge and reward the progress made. If you see better on-time delivery rates or reduced lead times, celebrate these wins. Recognizing and rewarding achievements can reinforce the desired habits within your organization. If your KPI’s are met, celebrate so employees gain motivation.

How to make your bad habits in business unattractive

Inverting the habit loop by making habits: invisible, unattractive, difficult, and unsatisfying. If these principles are applied into the framework of supply chain management it will be helping you to eliminate or diminish detrimental habits and improve the efficacy of your business.

- Make Bad Habits in Your Supply Chain Invisible:

Identify the problematic habits within your supply chain. This could include inefficient processes, poor inventory management, or communication bottlenecks. Once identified, work on making these habits less visible by removing cues and triggers that lead to them. For instance, if late deliveries are a recurring issue, identify and eliminate the causes of these delays.

- Make Bad Habits Unattractive:

Highlight the negative consequences of the bad habits in your supply chain. Showcase how these habits lead to increased costs, customer dissatisfaction, or missed opportunities. Emphasize the potential risks and drawbacks of maintaining these habits. This will make them less attractive to your team and stakeholders. You could penalize team or stakeholders whenever targets are not met, for example by needing to work overtime to finish your tasks.

- Make Bad Habits Difficult to Continue:

Introduce barriers and obstacles that hinder the continuation of bad habits. For example, if overordering is a problem, establish stricter inventory control measures that make it harder to place excessive orders. Implement policies and procedures that discourage the repetition of inefficient or costly habits.

- Make Bad Habits Unsatisfying:

Associate negative consequences with the bad habits to make them unsatisfying. This might involve highlighting the financial losses, customer complaints, or wasted time resulting from these habits. Reinforce the idea that indulging in these habits leads to negative outcomes, creating a sense of dissatisfaction among those involved.

Introducing a Powerful New Tool: Pigment

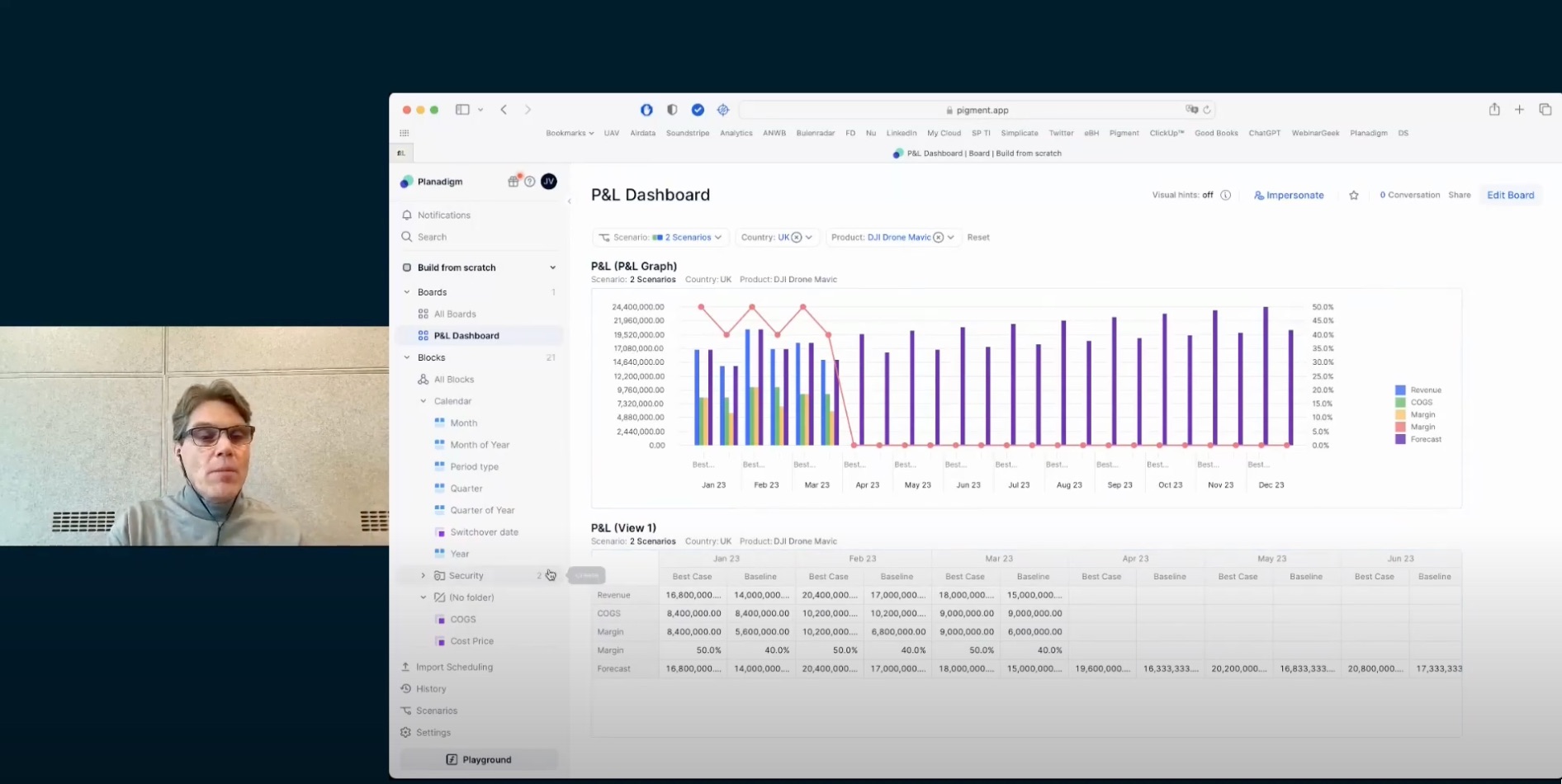

To effectively implement these small, strategic changes and manage your supply chain efficiently, a cutting-edge tool could be vital. Pigment is a revolutionary platform that integrates seamlessly with your existing supply chain infrastructure, providing real-time data, analytics, and automation capabilities. Here’s how it can help you transform your supply chain using the principles of atomic habits:

- Data-Driven Insights:

Pigment gathers and analyzes data from all aspects of your supply chain, helping you identify the cues and areas that need improvement. The platform provides actionable insights, empowering you to make informed decisions.

- Process Automation:

The platform allows you to automate repetitive tasks, reducing the risk of human error and enhancing efficiency. This aligns with the response stage of atomic habits – implementing small changes for long-term gains.

- Collaboration and Communication:

Pigment facilitates improved communication with suppliers, partners, and internal teams, addressing the cue of communication breakdowns in the supply chain. Real-time collaboration features ensure everyone is on the same page.

- Performance Tracking:

You can track the performance of your supply chain and visualize your progress, reinforcing the habit loop with rewards for improvements. Pigment makes it easy to measure and celebrate success.

Conclusion

In the dynamic world of modern business, where supply chains serve as the backbone of organizations, the integration of the principles from “Atomic Habits” by James Clear presents an exciting opportunity for transformation. The synergy between supply chain management and the habit loop offers a structured framework for achieving remarkable results through gradual, consistent change. Which will supercharge your organization to exceeded expectations.

We have explored how to apply the four steps of habit formation—cue, craving, response, and reward—in the context of supply chain management. Identifying cues, creating a craving for improvement, implementing strategic responses, and celebrating progress can help organizations refine their supply chains and enhance their competitive edge.

Moreover, we’ve discovered the power of inverting the habit loop to break detrimental habits within your supply chain: making them invisible, unattractive, difficult, and unsatisfying. This innovative approach serves as a formidable tool for eradicating inefficiencies and adopting a culture of continuous improvement.

To facilitate the seamless integration of these principles into your supply chain management, we introduced a cutting-edge tool: Pigment. This cloud-based planning tool offers real-time data insights, process automation, enhanced collaboration, and performance tracking. Pigment empowers organizations to put theory into practice by providing a platform for making informed decisions, automating processes, and tracking progress.

In the pursuit of supply chain optimization, the union of atomic habits and powerful tool like Pigment promises to revolutionize the way businesses operate. By understanding and leveraging the habit loop, your organization can transform the inefficiencies that once held you back into the strengths that propel you forward. Through incremental changes, strategic responses, and data-driven insights, you’ll create a supply chain that is not just efficient but also adaptable and resilient in the face of ever-evolving challenges. So, embark on this journey of continuous improvement, and watch as your supply chain becomes the cornerstone of your business success with the help of Pigment and the adoption of James Clear’s method.

Information was retrieved from the book Atomic Habits by James Clear.

Let us know your thoughts on the topic in this blog. You can reach us at info@planadigm.com or +31 6-51884701.