What is the added value of progress

Introduction

What is the added value of progress? This is a question that is difficult to answer…upfront. Looking at our projects and how the end results impacted the way of working for our customers, the added value can be huge. But how do you know the value upfront, before you start a project?

To turn that question around, what are the (hidden) costs of doing nothing? What if we keep doing wat we’ve been doing, if we do not start that project? It works, right? But to what costs? Which inefficiency do we keep alive by not changing?

The need for change is NOW

We have been active in the never boring and always exciting world of supply chain and supply chain planning. Looking back at how Sales & Operations Planning (S&OP) or even Integrated Business Planning (IBP) works within (most of the) companies, not much has changed. The planning process is labor intense, lots of non-added value activities and with the use of several different tools and platforms that somehow need to be connected. By the time a plan has been approved and put into action, the next planning cycle starts. And a huge effort needs to be done if a large event happens during the execution that disrupts the day-to-day operations, pushing supply chain professionals in a reactive mode. Respond to what happens and work your way through the madness trying to make the best out of it.

But there are defining factors at play that demand a change now. Think of:

- Aging workforce (outflux of knowledge).

- Geopolitics (war in Ukraine, Trump being elected, Russia – China collaboration).

- Introduction of new technologies (AI, cloud-based tools).

- Scarcity (personnel, raw materials, energy).

- Increased prices (personnel, raw materials, energy, transportation).

The conclusion is simple: we need to do more with less and for that, we need to become more effective and efficient.

ROI

We started this article by asking what the added value of progress is. Progress can be made by investing in personnel, software, machines, processes, you name it. Or the time spent by your employees on projects. But how do you know upfront what the Return on Investment (ROI) will be? Do we need to invest in that training for our planners, do we need to buy those new machines, do we need to hire that consulting firm to improve our planning process and/ or tools? The short answer: you don’t know. ROI calculations upfront are full of assumptions, you can only be sure afterwards…after the investments have been made.

We strongly advise to calculate the expected ROI upfront. Not using ROI calculations is like driving in the fog at 100 kilometers an hour and hoping you arrive and safe and in time and in the right destination. Too many uncertainties! Using a tested and proven ROI calculation tries to minimize the uncertainties as much as possible, it provides for better prepared decisions and allows for changes along the way.

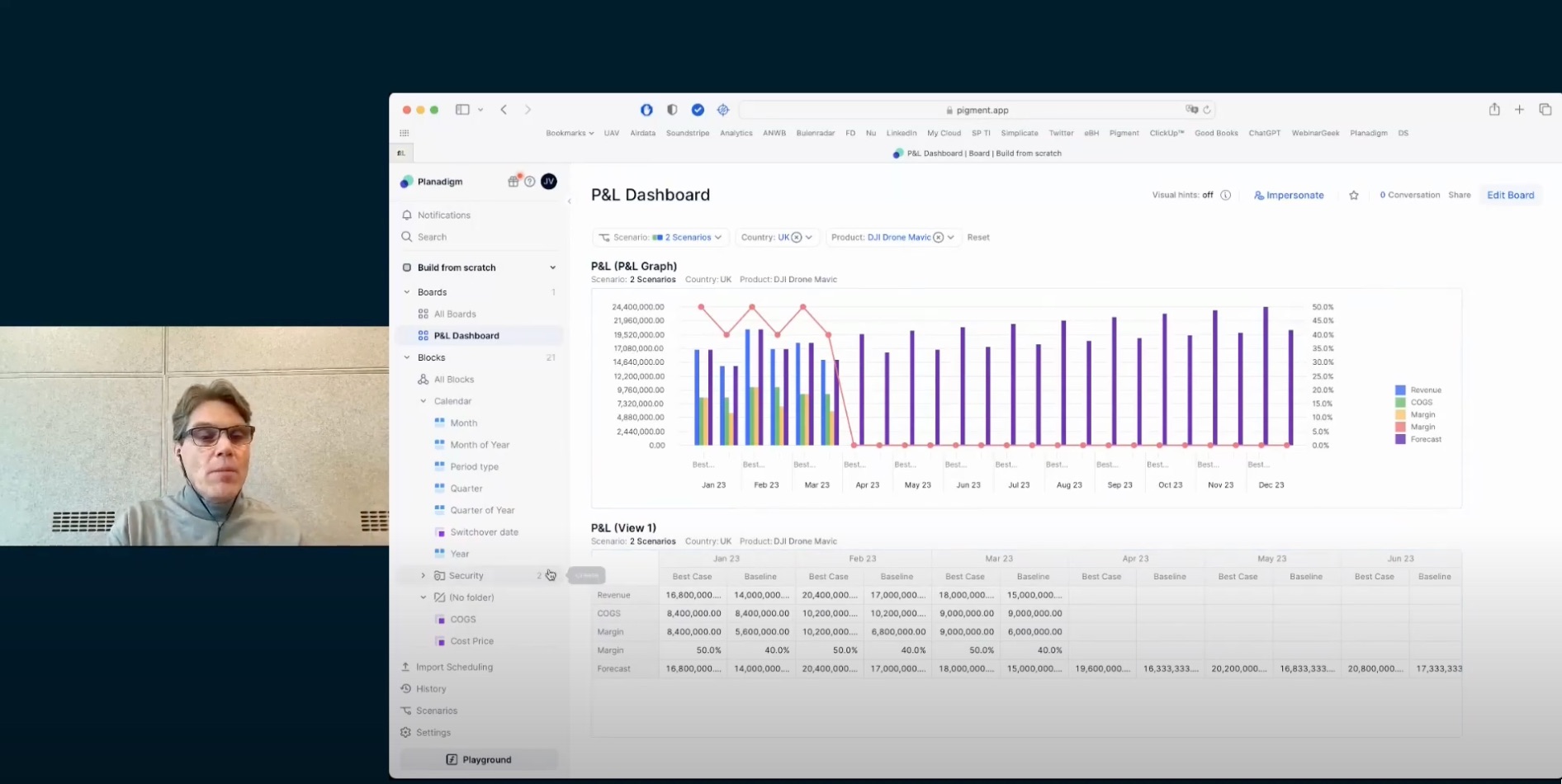

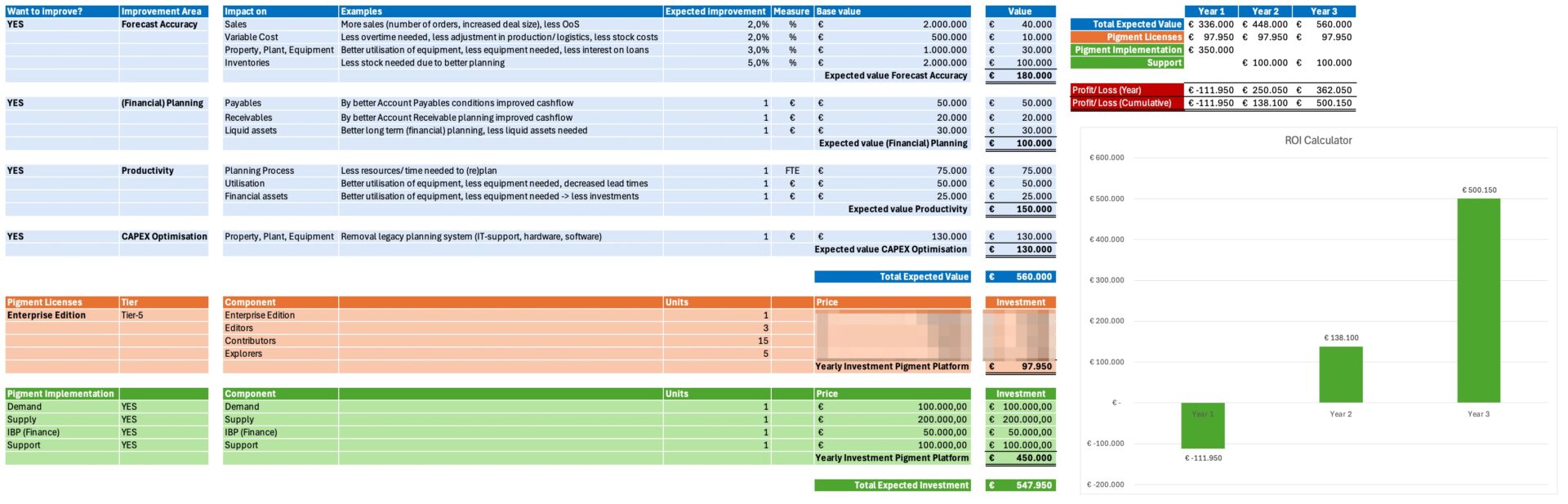

ROI-calculator

At Planadigm, we have created a ROI-calculator. This calculator is based on the financial DuPont-scheme and translated into supply chain areas. For example, if we discuss the option to improve the forecast accuracy, this will impact several areas:

- Stock levels.

- (Lost) sales.

- Process efficiency gains.

- Reduced bullwhip effects.

Together with a customer, we will sit and define the possible areas for improvement. We will ask and challenge the expected percentage improvement and the current base for each improvement area. Example: the customer thinks that with a forecast accuracy improvement of 10%, the current stock levels can be decreased by 5%. The current (average) value of stock at hand is €5 million, resulting in a saving of €250.000.

We will cover all possible areas for improvement and add up the calculated savings. We estimate the costs for the project (external consultants, software licenses) so we can calculate the expected ROI over the next years. Some projects start to generate a positive ROI in the first year, some from the second or even third year onwards. If the expected ROI stays negative, you have the answer to the question if you should invest.

Always calculate the expected ROI

Our advice: always calculate the expected ROI! Together we can calculate the expected benefits and costs and based on the outcome, the customer can make informed decisions. It is not a guarantee that the expected ROI will be achieved, but we have seen also the other way around, the final ROI outperformed our expectations, by far.

The main reason to use our ROI-calculator is to make informed decisions. Should you invest in progress and if so, which project(s)? Also prioritizing projects based on expected ROI can help in allocating the scarce resources to the right initiatives at the right time.

Our ROI-calculator can be the starting point of the discussion in which initiatives to invest and when. Interested in how we can support your journey to greater excellence? Give us a call and we are more than happy to show you how we calculate the expected ROI for your supply chain projects. You can reach us at jan.veerman@planadigm.com or call us at +31 6 5188 4701.