Pillars of Supply Chain Resilience

How to build a future-proof supply chain resilience by strengthening Visibility, Agility, Collaboration, and Control.

Introduction

Resilience. A word that pops up a lot nowadays, especially in supply chain. But what does it mean? According to the Dictionary, resilience is:

noun

- the capacity to withstand or to recover quickly from difficulties; toughness.

“the remarkable resilience of so many institutions - the ability of a substance or object to spring back into shape; elasticity.

“nylon is excellent in wearability and resilience”

In short: the ability to recover quickly from events happening in your supply chain and continue your operational activities.

The reason why resilience has become such a hot topic is due to a couple of events that has happened in the last years:

- COVID-19

- Scarcity (raw materials, personnel)

- Geopolitics (war Ukraine, import tariffs, trade war)

Before COVID-19, supply chains were a well running machine: just in time (JIT) deliveries, optimized stock levels, ability to match demand with supply (in most cases). Due to the mentioned events, supply chains have been destabilized. Shortages came to surface, like raw materials and the ability to find the right personnel. Increased prices of materials, personnel and transportation caused changing demand patterns around the globe. Demand became less predictable, supply chain less forecastable, the need to become more resilient was born.

Building resilience starts with strengthening the four key pillars that support it. In this blog, we’ll explore what those pillars are and how you can apply them in your supply chain to boost both agility and resilience. The four pillars of resilience are:

- Visibility

- Agility

- Collaboration

- Control

Visibility

Visibility is the end-to-end visibility of your supply chain. It starts with the demand signal coming from your customers and ends with the capabilities of the suppliers of your suppliers. How well are you able to predict future demand? Have you incorporated external data that are relevant indicators to your customer demand in your forecast? Think of socio-economic data, trends, inflation rates, all indicators that could influence buying behavior of your customer.

And knowing the capacities, stock levels, and quality controls of your suppliers is not enough. What are the suppliers of your suppliers doing? Are they capable of ramping up or down fast enough? What are their quality controls? Do you get early warning signals if they cannot deliver?

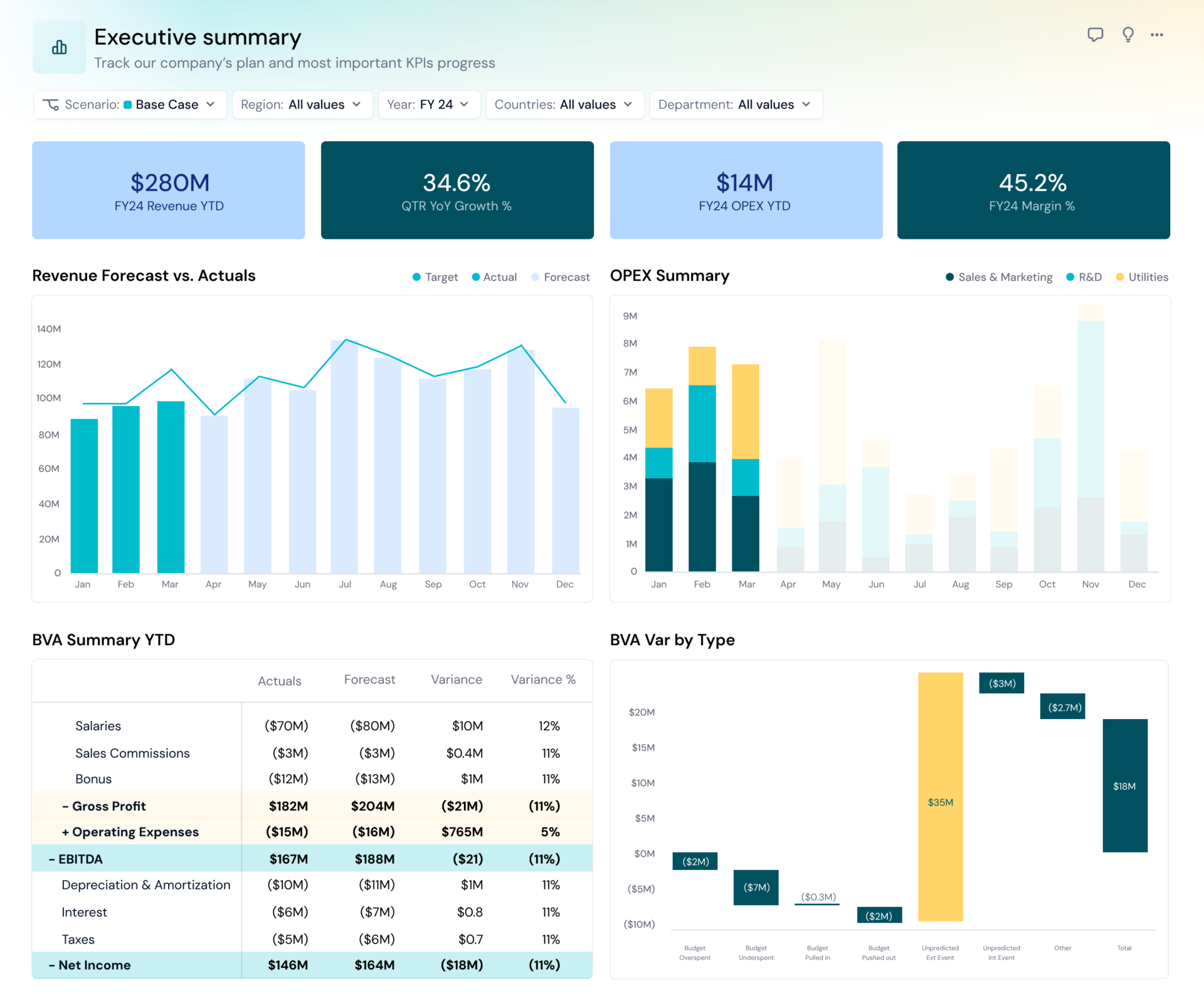

The more visibility up and downstream in your supply chain, the better. The faster information flows, the quicker you can respond. Instead of reactive, you become proactive. Technology plays a major role in increasing visibility. Automation of data flows, early warning signals, and automated data analytics (with the use of Artificial Intelligence – AI) does increase the speed of reaction. And another, very important component, is trust. Trust is key: if you cannot trust your suppliers (or vice versa), you will not receive the right information in time. Building trust requires time, but the payoffs for all parties can be huge. And value chains will win in competition, not isolated companies!

Agility

Agility is the ability to be flexible, to adjust your plans, to switch suppliers, to ramp up or down your production capacity, to outsource. You can achieve this in part by expanding your supplier network, outsourcing production, and using a flexible workforce — essentially, increasing your options. This allows for the mandatory flexibility to respond quickly to changes in plan.

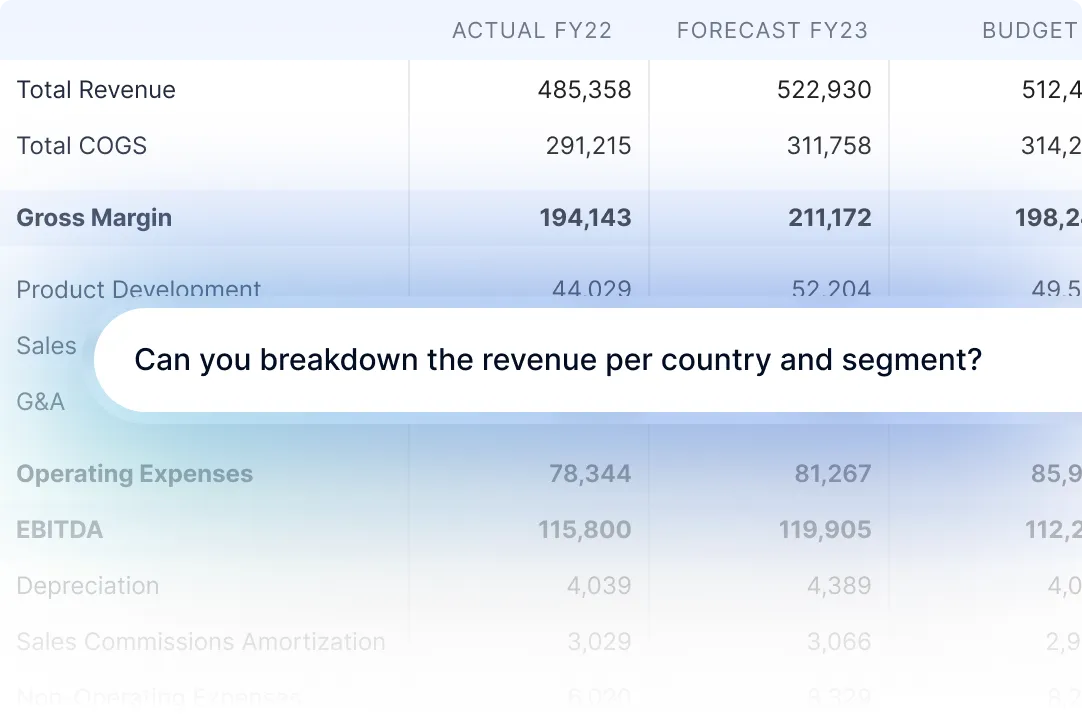

Technology can play a big part in this pillar as well. With the use of analytical tools, you can analyze huge amounts of data fast. AI can handle much of the heavy lifting typically done by humans, generating initial insights that accelerate decision-making by a factor of at least 10x — while freeing up your team’s time to focus on making the right decisions faster. For that, you need to have the right data (from internal as well as external data sources), the right technology (planning & analytical tools) as well as the data analytical skills in your team.

Collaboration

Collaboration is key! In supply chains, no one can do all by himself. So, you need to build a network of strategic partners, up and downstream. Think of logistical provides, consumers, external production capacity, suppliers, suppliers of suppliers. Controlling this value chain has become critical. Working as a well-oiled machine and sharing information on a frequent base (minutes instead of days) will allow all partners in your supply chain to reap the benefits of being resilient (read: increase margins for all involved) and push for a tighter relationship.

Also, allow yourself to switch quickly. If your preferred supplier A cannot deliver, be able to get the same quantity and quality from supplier B. What COVID-19 made painfully clear is that supply chains are in need to diversify in suppliers!

Again, technology can play a big role here: the faster the information flows, the easier it is to adapt. And trust, as mentioned before, is key for excellent collaboration. You need to be able to trust your strategic partners to gain the benefits. Agree on long term goals with your value chain partners and divide the benefits according to the effort and investment each partner puts in.

Control

This last pillar is all about your influence in the value chain. How much control do you have, and how big a say do you have as a company in decisions that impact the full value chain? The same goes for rules & regulations. How much freedom do you have to operate (within boundaries) to adjust your plans, processes, and ways of working? The larger your control, the more flexible you can be.

Control also applies to the analytics component. The more insights you have, the earlier warning signal from the value chain reaches your organization, the more control you have on the available options. This increases your flexibility and resilience.

Conclusion

To become and stay resilient, you need to pay attention to all four pillars as described above. The old ways of working do not apply anymore. Just-in-Time (JIT) has become Just-in-Case. The option to have several suppliers for the same raw materials, the option to stock more inventory at different stages and locations in your supply chain, the ability to share more data with your value chain partners. Actions taken to become more resilient, to respond quicker to events happening in the supply chain, to make sure you can meet demand with supply. And stay relevant for the future!

Let’s hear your feedback: how do you stay resilient today; what actions did your organization take to increase resilience and stay relevant? Please let us know via jan.veerman@planadigm.com.

Contact