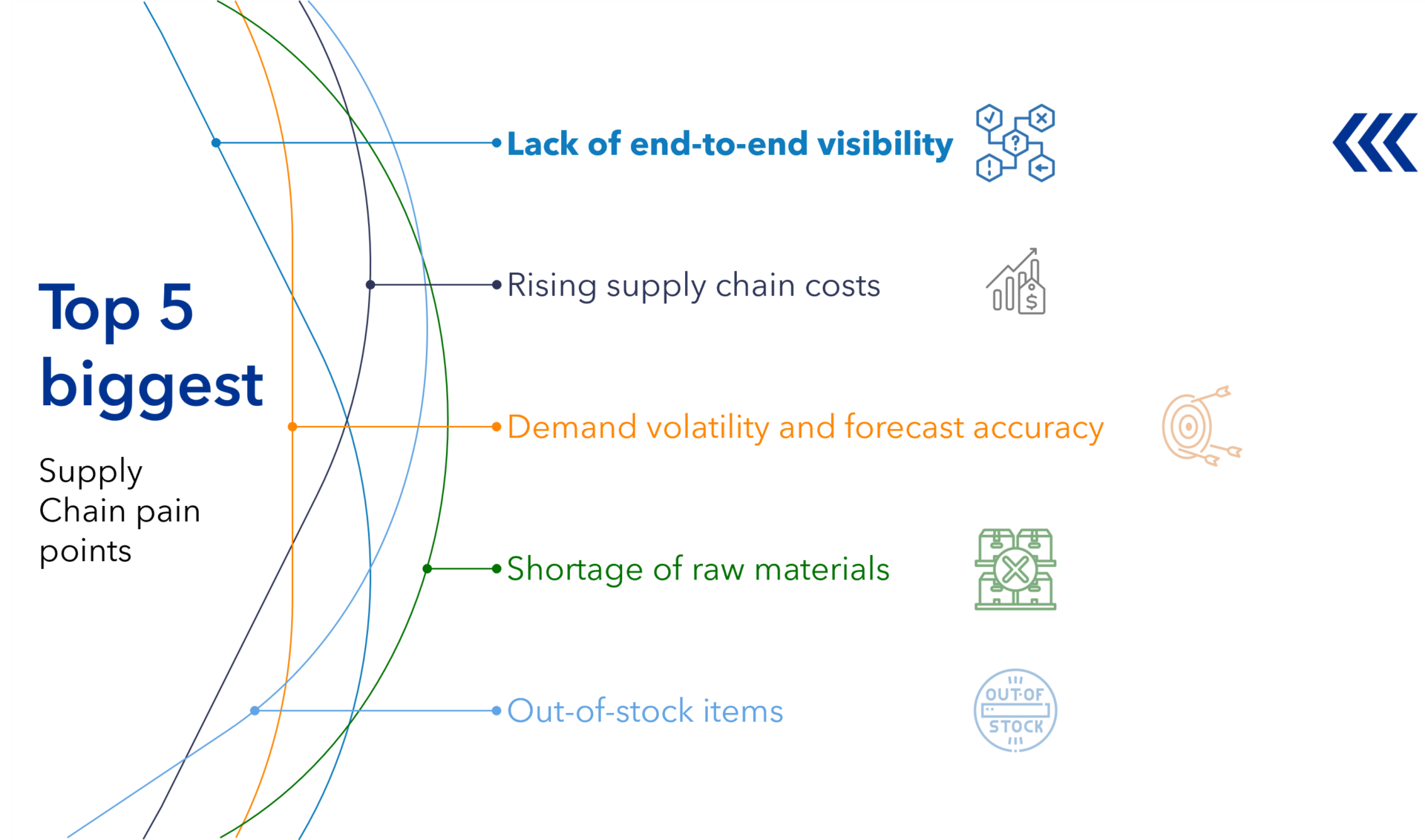

Top 5 biggest Supply Chain pain points - #1 Lack of end-to-end visibility

Introduction

In a series of five blog posts, we are going to do a deep dive on the top 5 biggest supply chain pain points, experienced by the business. How did we came up with this top 5? By researching the Internet to look for articles that describe current pain points and keep score of the number of articles. And by the interactions we had with our customers, we listened to the issues they brought to the table.

In this blog post we’ll do a deep dive on the pain point ‘lack of end-to-end visibility’, what is the impact on the business if not addressed and how it can be solved.

What is a lack of end-to-end visibility?

With a lack of end-to-end visibility, you are not able to oversee you full supply chain. You can see most of it, but parts are invisible to you. That could be upstream, your suppliers or the suppliers of your suppliers. That could also be downstream, your customers.

By far, this issue was mentioned the most. Before COVID, global supply chains were optimised and tuned to deliver the required output. Goods were delivered just in time (JIT), inventories were kept at a minimum and only at specific end points. The need to look further into your supply chain was lacking, the supply chain processes ran well and were predictable (up to a point).

During and after COVID, supply chains got disrupted. Uncertain demand, shortages, increased pricing, delivery issues…up till today, many supply chains are still struggling to find a new balance. By extending the visibility of the supply chain, companies try to get a better view, be better prepared.

What is the impact of seeing only a part of the supply chain?

When you can only oversee a part of your supply chain, you will not see disruptions coming your way in time. Your ability to respond in a timely manner will be diminished the later to see these disruptions. You are in a constant fire fighting mode, which we see across the market. Every supply chain professional we connect with, is struggling with day-to-day operational challenges. Dealing with shortages of raw materials, shortages in labour, increased pricing of materials, volatility in the demand, lost sales.

Instead of looking at the future and work on strategic and tactical supply chain improvement activities, solving operational issues has taken over the agenda. The ability to improve processes, agreements, collaborations, tooling has become impossible due to the heavy, operational work load.

If you can oversee only your own part of the supply chain, you will always be surprised by the disruptions caused upstream. A severe delay in materials from your supplier, a shortage on their side, any disruption will come as a surprise, leaving you little to no time to respond in a proper way. This leads to fire fighting and issue solving actions, instead of the more added value actions to improve your supply chain processes.

If every part of the chain is solving his own issues, the result of the full supply chain is suboptimal. Aligning with your suppliers and with your customers is beneficial for all stakeholders involved.

How to create end-to-end visibility

There are several ways to extend the end-to-end visibility:

- Work on tighter collaboration

- Share specific and more information

- Build trust across the supply chain

- Invest in a platform that allows more transparency

The biggest hurdle to take is building and increasing the trust amongst the stakeholders. If you are not willing to share relevant information with your suppliers (or vice versa), extended visibility will become difficult. You need to start to trust each other, part of it needs to come from contractual agreements, part of it needs to come from an improved alignment, resulting in more sales and less costs for all parties involved.

Once the trust part has been overcome, relevant data can be shared. For example, if your supplier cannot deliver in time due to a disruption, that signal should reach you as soon as possible. You are then able to readjust your plans in time. It also works the other way around: if you have an unexpected spike in demand, that signal needs to move upstream to your suppliers as soon as possible to make sure they deliver the additional supplies.

With the proper tooling, you can connect your suppliers and even the suppliers of your suppliers. You might want to start with the 20% of suppliers that deliver 80% of the (raw) materials. The same goes for your best customers. Why forecast their demand (which is uncertain)? Instead, connect them to your planning platform and ask them to enter their demand on a regular base. Technically, nothing is holding you back to connect your suppliers and customers to one platform. A platform like Pigment can connect all stakeholder. Based on security settings, each stakeholder only will see what you allow them to see. But as mentioned, the trust issue needs to be solved first.

Conclusion

End-to-end visibility is the number one supply chain pain point for a lot of companies. And it is clear why. With better visibility of your supply chain, up & down stream, you are better prepared for all the disruptions. And disruptions will occur, that is a certainty.

The earlier you get the signals of these disruptions, the better you can plan for alternatives. Alternatives like other suppliers, adjusting the plan to meet the additional demand, bringing forward production and build up inventory to cope with additional peak demand later.

Having end-to-end visibility is a win – win game for all stakeholders involved. Suboptimal planning is replaced with more optimal planning, lowering costs and increasing sales. Companies will get more resilient due to the fact events will be notified earlier and allowing you to respond in time.

We were not surprised this is the biggest pain point mentioned. We hardly come across companies that have extended their visibility of the supply chain, but the need and benefits are huge. And the good news is, it can be solved. With easy steps (see above), the first steps towards end-to-end visibility can be taken, the impact and effects can be monitored to see the benefits.